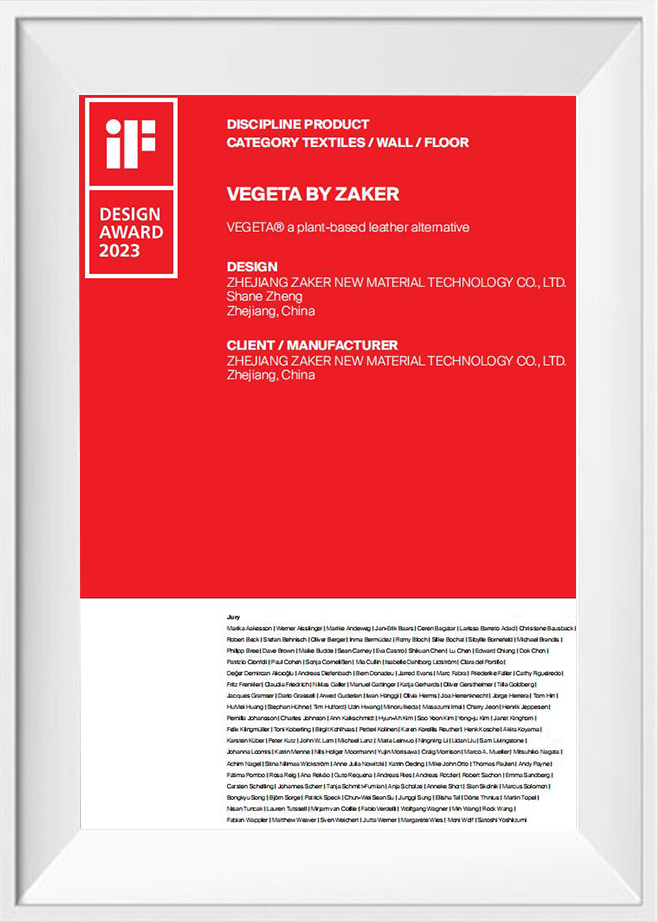

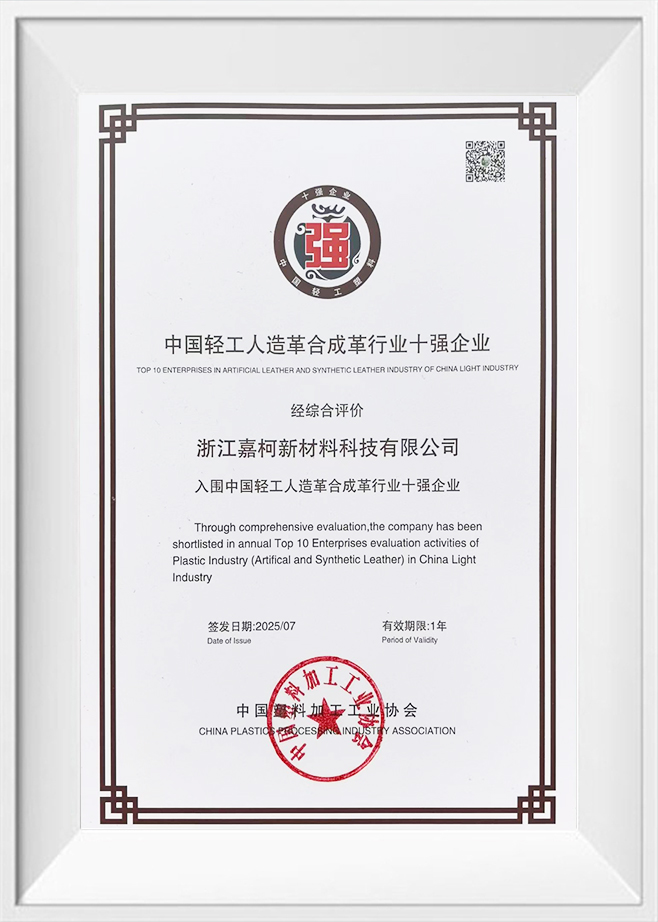

ZAKER is an artificial leather and synthetic leather factory dedicated to the research and production of water-based and bio-based materials. Leveraging a modern production base of nearly 50,000 square meters and over 100 patent technologies, it focuses on the exploration of low-pollution, plant-based, and recyclable new materials, continuously promoting the green transformation of the industry, and through its independent innovation technology platform, forming a diversified product system centered on water-based synthetic leather, biogenic synthetic leather, and functional high-end coating materials, which are widely applied in fashion clothing, luggage, shoe materials, home furniture, automotive interiors, consumer electronics, and other fields.

Innovative products developed on water-based production processes and bio-based raw materials.

The application of bio-based waterborne polyurethane in synthetic leather manufacturing provides a sustainable material option for fields such as fashion, automotive interiors, and home furnishings. Building on this, chemical-based high-value recycling and utilization of waste synthetic leather are carried out. Methods like chemical depolymerization are used to convert it back into usable monomers or raw materials, forming a complete sustainable closed-loop of "production - use - recycling - reproduction". This greatly improves the material recycling rate, shifts from a linear model to a circular one, and achieves Upcycling.

Circular Recycling Technology: Lab R&D to Pilot Scale Stage

information to be updated

-

2025.08.22Advantages of Water-based Production ProcessWater-based production processes use water as the primary solvent or dispersion medium. They are widely used in a variety of industries, including coatings, adhesives, inks, leathe

-

2025.08.22Innovative Application of Coconut Into LeatherThe innovative use of coconut in leather is a very interesting sustainability topic. This combination not only reduces the demand for traditional leather but also utilizes coconut

English

English