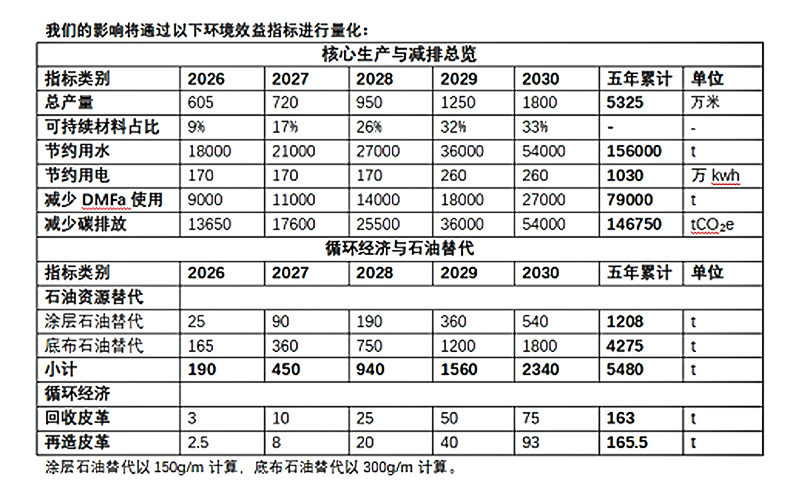

By 2030, we will have cumulatively saved 156,000 tons of water (equivalent to the capacity of 75 standard swimming pools).

We will cut 10.3 million kWh of electricity use (equal to the annual power consumption of 2,000 households) and reduce 147,000 tons of carbon emissions (equivalent to taking 100,000 vehicles off the road for a year).

Within five years, we will completely eliminate the use of approximately 79,000 tons of toxic DMFa solvent, fundamentally safeguarding workers’ health and the ecological environment.

Leveraging circular technologies, we will recycle and regenerate over 328 tons of waste leather, and cumulatively replace more than 5,480 tons of petroleum-based raw materials, significantly reducing dependence on fossil resources.